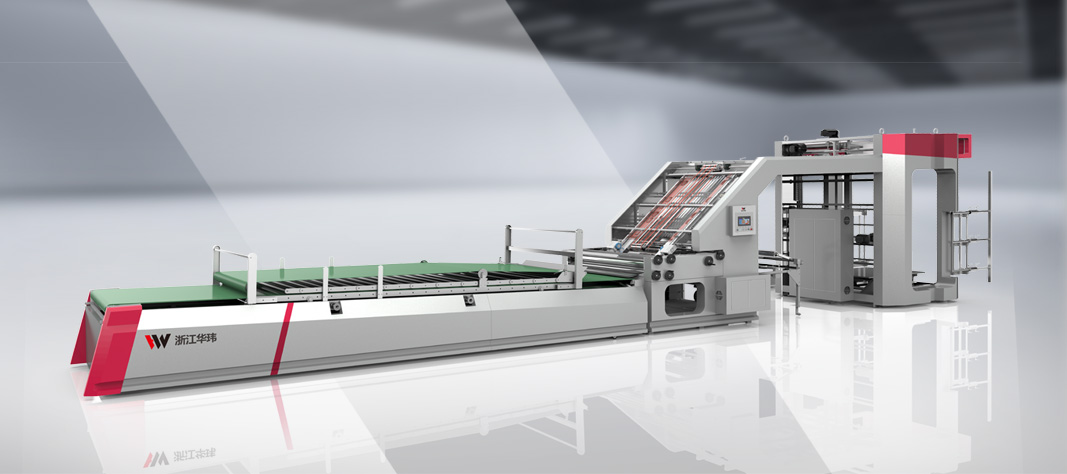

Fastness, Flexibility, Intelligence, Stability, Efficiency,

Different From Other Devices

Fastness, Flexibility, Intelligence, Stability, Efficiency,

Different From Other Devices

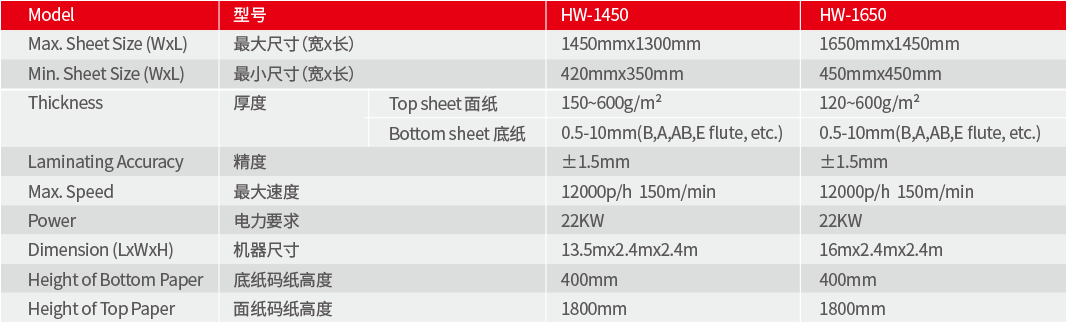

HW-1450/1650/1900

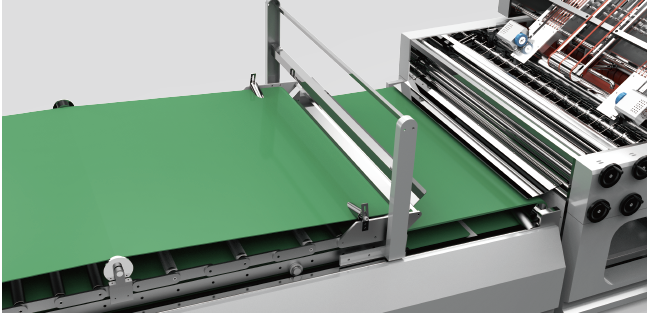

Automatic High Speed Flute Laminator

1. Computerized high-speed lamination, the maximum speed is 180 m / min (depending on paper).

2. The paper feeder adopts E-type lifting plate, which can push the paper to be bonded into place by a hydraulic vehicle, and an optional additional track with a pre-coded paper device can be optionally installed.

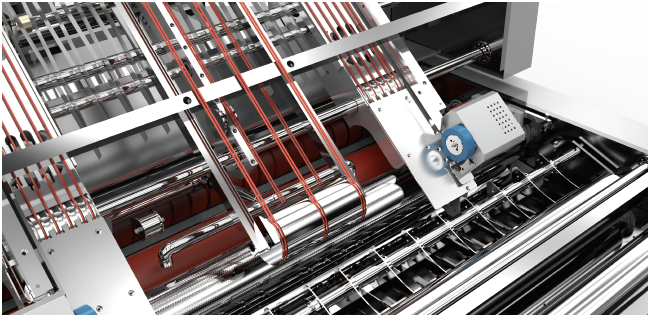

3. Feida adopts four-suction, four-feed paper feeding, high-speed and stable, continuous sheet.

4. Sensing compensation registration device, using multiple sets of electric eyes to sense the relative position of the bottom paper forward, so that the servo motors on both sides of the face paper can independently transmit and compensate the upper and lower paper registration, which is accurate and smooth.

5. Full-function electrical control system: the application of human-machine interface and PLC program light display, can automatically detect the operating conditions, abnormal display, electrical design in line with CE standards.

6. Glue coating device: The high-precision coating wheel is matched with the special metering steel roller to make the glue more uniform.

The unique glue wheel blocking mechanism and automatic liquid level control. High-speed running without glue overflow can adjust glue backflow.

7. The bottom paper conveying part adopts high-power servo motor control system with high sensitivity and fast speed. The bottom paper suction adopts high pressure blower and SMC large flow control valve. The unique dust collection filter box design guarantees high-pressure adsorption, suitable for different corrugated papers, achieving high-speed operation without paper jams, and continuously feeding paper smoothly.

The lower suction belts driven by servo motor match suction belts of NITTA and SMC High frequency valve to assure accurate sheet feeding. Pneumatic bar can press the front edge of boards for smooth feeding when the boards are curved.

High-speed Paper Laminator To Help You Complete Impossible Tasks

1. High precise coating stainless steel roller mechanism assures even adhesive applied.

2. Special mechanism ensures paper strippingoff the gluing, roller, easy to, clean, dismantle andadjust.

3. Three sensors to control the glue volume level automatically.

4. Side Glue stopper ensures no overflow at high speed and glue re-circulation at high speed.

The machine adopts multiple sets of photoelectric sensor at bottom sheets relative position, control top sheets on both sides of the servo motor to do independent compensation action, which accurate positionof top paper and the bottom paper.